Main mechanical hazards_Rubber Processing

- Written by Super User

- font size decrease font size increase font size

Feeding ingredients and collecting compound

The principal dangers and safeguards on a Banbury type internal mixer are:

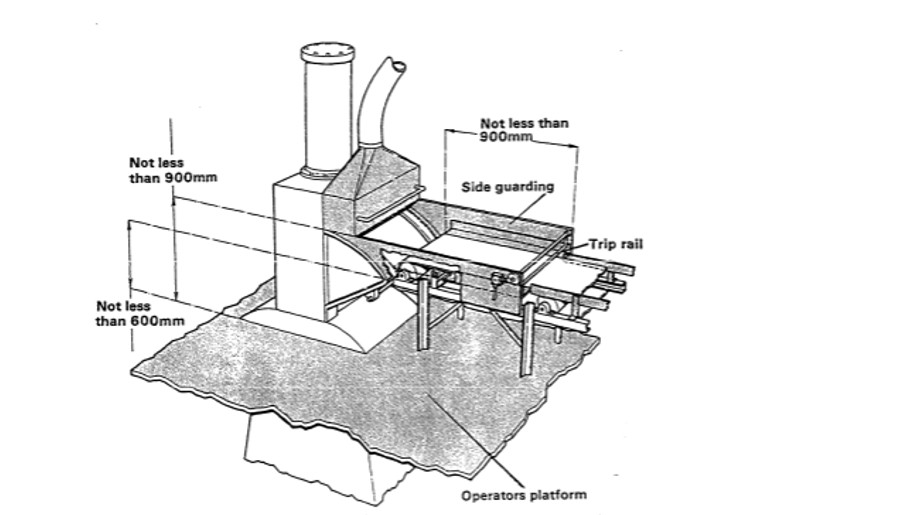

- The rotors, via the feed opening (contact with rotors or falling in on larger machines) These risks can be guarded against by feed tables or conveyors placed in front of the feed opening, with additional fixed side guards, where necessary.

- Safe reach distances should meet the requirements of Table 4 of BS EN ISO 13857: Safety of machinery. Safety distances to prevent hazard zones being reached by upper and lower limbs.

The floating weight trap with the fixed bridge casting from either the feed opening or the rear inspection door. There should be sufficient clearance between the bridge and the fixed bridge casting to prevent a finger-trapping hazard. Prevent access by using the same safeguards as for the rotors. - The floating weight and the lower edge of the front hopper door at the feed opening. The trap at the bottom of the weight is more dangerous. Operators are at risk when sweeping down or when adding lubricant or other small ingredients. Where access to the trap is possible, interlock movement of the floating weight with the hopper door.

- The front hopper door and frame as the door closes and the stops as it opens under power Where powered movement of the door creates a trapping hazard, it's operation should be via a hold-to-run control, located out of reach of the door or a two-hand control on the hopper itself. A front feed table preventing access will also improve safety. Where bin-tipping units feed mixers, enclosing interlocking guards are required to prevent access to shear traps created by the tipping mechanism.

Latest from Super User

Login to post comments